Digital factory丨Chenen online and offline, software and hardware together to implement measures

Release time:

2023-04-13

Since February, Suzhou Chenn actively responded to the government's call for epidemic prevention and control, and shifted the epidemic prevention and control to be carried out on a regular basis. For the online telecommuting that may appear at any time, Suzhou Chenn technology department participated in developing a highly integrated and digital intelligence enterprise resource management system with full data opening from front-end to back-end.

Since mid-February 2022, the national epidemic situation has been repeated. after mid-March, the epidemic situation in Kunshan, Taicang and other areas gradually became severe due to the spillover of the epidemic in Shanghai, and the pressure of epidemic prevention in the large city of Suzhou increased steeply. Under the normalization of the epidemic, Suzhou Chennai, in order to ensure the normal production of compressors, has been working together online and offline to promote the transformation of the digital factory and actively deal with a series of uncertainties in the supply chain and telecommuting that may be brought by the epidemic.

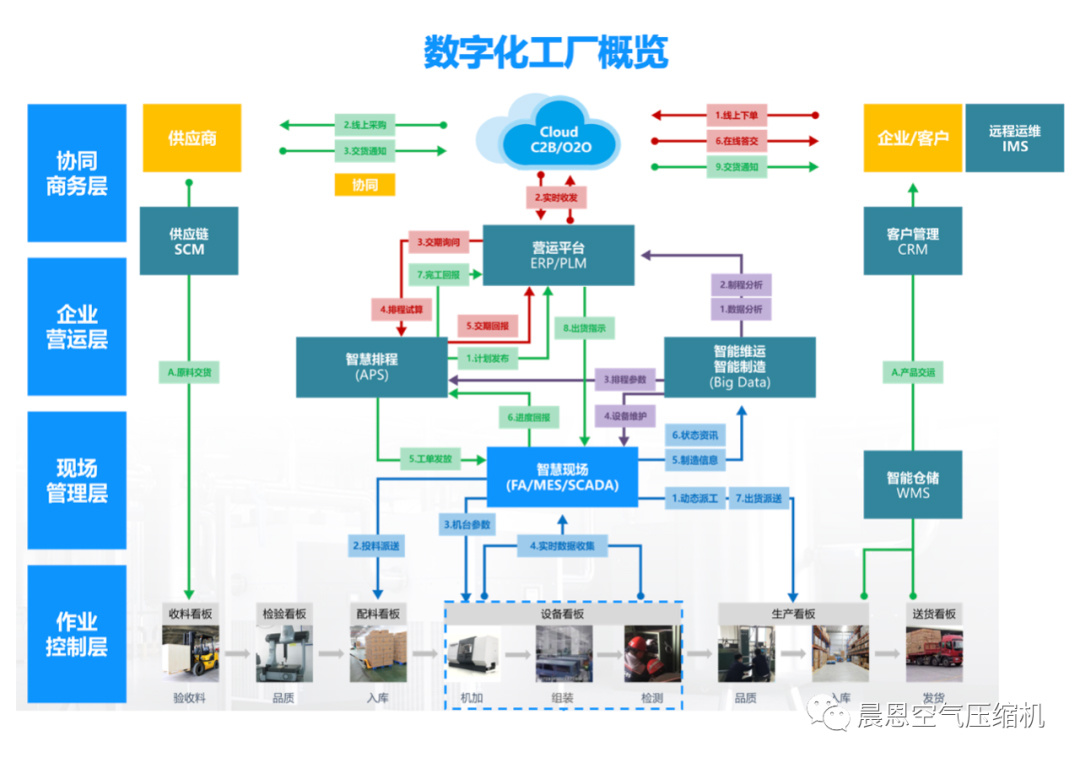

Since February, Suzhou Chenn actively responded to the government's call for epidemic prevention and control, and shifted the epidemic prevention and control to be carried out on a regular basis. For the online telecommuting that may appear at any time, Suzhou Chenn technology department participated in developing a highly integrated and digital intelligence enterprise resource management system with full data opening from front-end to back-end.

Zhao, manager of Suzhou Chenn's screw compressor division, said, "This system not only covers the traditional back-end ERP execution system, but also integrates the front-end CRM business layer and service management with the equipment IoT."

Chenn staff can deal with the whole process from the remote cell phone APP end, and can also remotely monitor the compressor equipment parameters in real time, manage the whole life cycle of the equipment, send early warnings to the equipment that is about to fail, and realize remote maintenance and operation, so the user experience will also be greatly improved. As far as the production site is concerned, the collaborative work of SCM, MES system and ERP system will significantly improve the supply chain connection and production operation efficiency.

Digital transformation is an inevitable trend in the development of enterprises, and this is especially true for compressor manufacturers. As a compressor company committed to rely on the development of industrial digital intelligence, Suzhou Chensco will rely on 5G + Internet of Things as the starting point, so that product intelligence, service digitalization, internal collaboration synchronization.

Related news