What are the hazards of over-use of screw air compressor consumables?

Release time:

2023-04-13

Air compressor consumables are an important part of a permanent magnet inverter screw air compressor to extend its service life and are a major component of the cost. As an air compressor manufacturer, we believe that consumables cannot be saved! Let's see what are the hazards of over-use of air compressor consumables

Air compressor consumables are an important part of a permanent magnet inverter screw air compressor to extend its service life and are a major component of the cost. As an air compressor manufacturer, we believe that consumables cannot be saved! Let's see what are the hazards of over-use of air compressor consumables!

01

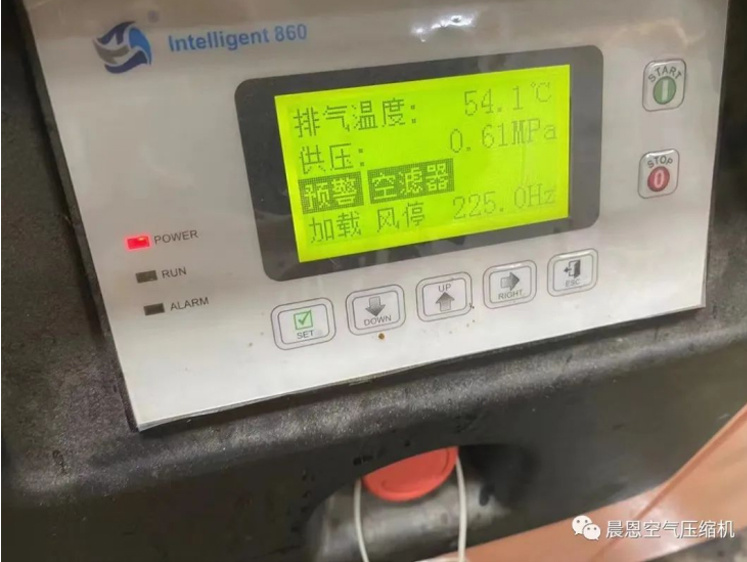

Air Filter

Function: The air filter element is an important protection barrier for the air compressor! The cleaner the air is, the better the service life of the oil filter, oil-gas separator and oil is guaranteed: to prevent other foreign objects from entering the mainframe, because the parts of the mainframe are very precise, and the important clearance is generally 30-150Ч, so foreign objects entering the mainframe will definitely cause harm to the mainframe and lead to the mainframe "holding "or even scrapped.

Air filter life: usually 1500-2000 hours, according to the working environment conditions are adjusted.

The hazards of over-use: insufficient exhaust volume of the unit, affecting production; excessive resistance of the air filter, increasing energy consumption of the unit; increase in the actual compression ratio of the unit, increasing the load of the main engine and shortening its life; broken filter element leading to the entry of foreign objects into the main engine and the occurrence of the main engine holding and even scrapping.

02

Oil and gas separator

2. Oil and gas separator

Function: Separate the oil in compressed air

Oil life: usually 1500-2000 hours, can be adjusted according to environmental conditions.

Hazards of overuse: poor separation efficiency, resulting in increased oil consumption, increased operating costs, oil shortage may even lead to host failure; compressed air outlet oil content increases, affecting the operation of the back-end purification equipment, resulting in gas equipment can not work properly; blocked resistance increases, resulting in the actual exhaust volume of the unit increases, increasing energy consumption; failure of the glass fiber material off into the oil, resulting in oil filter life shorten the life of the oil filter and the normal wear and tear of the main engine.

03

Oil filter

Function: To filter out the metal particles and magazines in the special oil for air compressor to ensure the cleanliness of the oil circulation system and protect the safe operation of the main engine.

Oil filter life: usually 1500-2000 hours, can be adjusted according to environmental conditions.

The hazards of overdue use: insufficient oil return, resulting in high exhaust temperature, shortening the life of oil and oil points; leading to insufficient lubrication of the host, seriously shortening the life of the host; filter elements such as broken, unfiltered oil containing a large number of metal particles magazine into the host, resulting in serious damage to the host.

04

Specialized motor oil

Function: Lubrication, cooling, sealing, vibration damping, unloading, protection, etc.

Lubrication: Improves friction conditions, reduces friction, prevents wear and tear, and also reduces power consumption.

Cooling effect: most of the heat generated during friction is taken away by the lubricant and a small portion of the heat is directly emitted through conduction radiation.

Sealing role: The seal between the yin and yang rotors of the air compressor is sealed with the help of lubricating oil.

Vibration damping effect: friction parts in the oil film movement, as if floating in the "oil pillow" on the same, the vibration of the equipment plays a certain buffering effect.

Unloading effect: Due to the presence of oil film between the friction surface, the action on the friction surface of the load is more uniformly distributed through the oil film on the friction surface, the oil film of this role is called unloading effect.

Protective effect: It can be anti-corrosion and dustproof, and play a protective role.

Oil life: usually 1500-2000 hours, can be adjusted according to environmental conditions.

The hazards of over-use: air compressor will have high temperature alarm and shut down; lead to the decrease of wetting effect and accelerate the wear and tear inside the unit; oil deterioration will cause coking and carbon accumulation inside the equipment.

Related news