Heat Wave - Air Compressor Heat? Here are the solutions to prevent high temperature failure

Release time:

2023-04-13

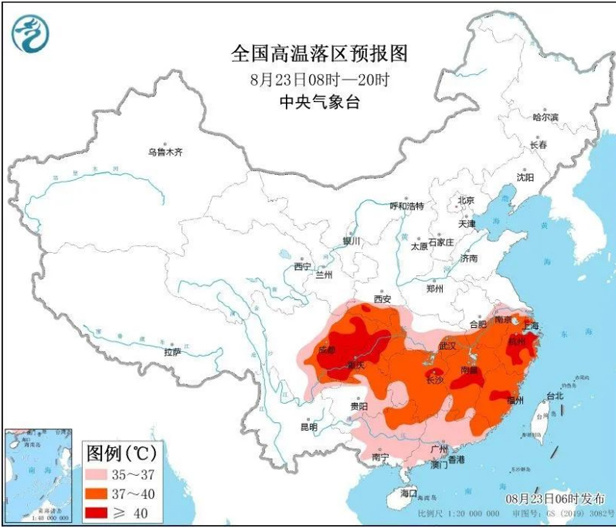

Recently, some provinces in China continue to be affected by high temperature weather, and the power supply has been challenged. The phenomenon is particularly prominent in some areas of Sichuan province, where the high temperature has led to production shutdowns and power restrictions for enterprises, causing a great impact on people's work and life.

Recently, some provinces in China continue to be affected by high temperature weather, and the power supply has been challenged. The phenomenon is particularly prominent in some areas of Sichuan province, where the high temperature has led to production shutdowns and power restrictions for enterprises, causing a great impact on people's work and life.

01

Air compressor room ventilation

In order to ensure timely heat dissipation of the compressor, the working environment of the compressor needs to have good ventilation, and no debris should be piled up around the machine when it is running to prevent the ventilation conditions. If possible, the manufacturer can equip the compressor with a compressor room with ventilation and cooling system.

02

Check for clogged air filter

Equipment managers should regularly check the air filter for blockage to ensure that the air filter is clean enough. A clean air filter can also reduce the operating temperature and energy consumption of the air compressor.

03

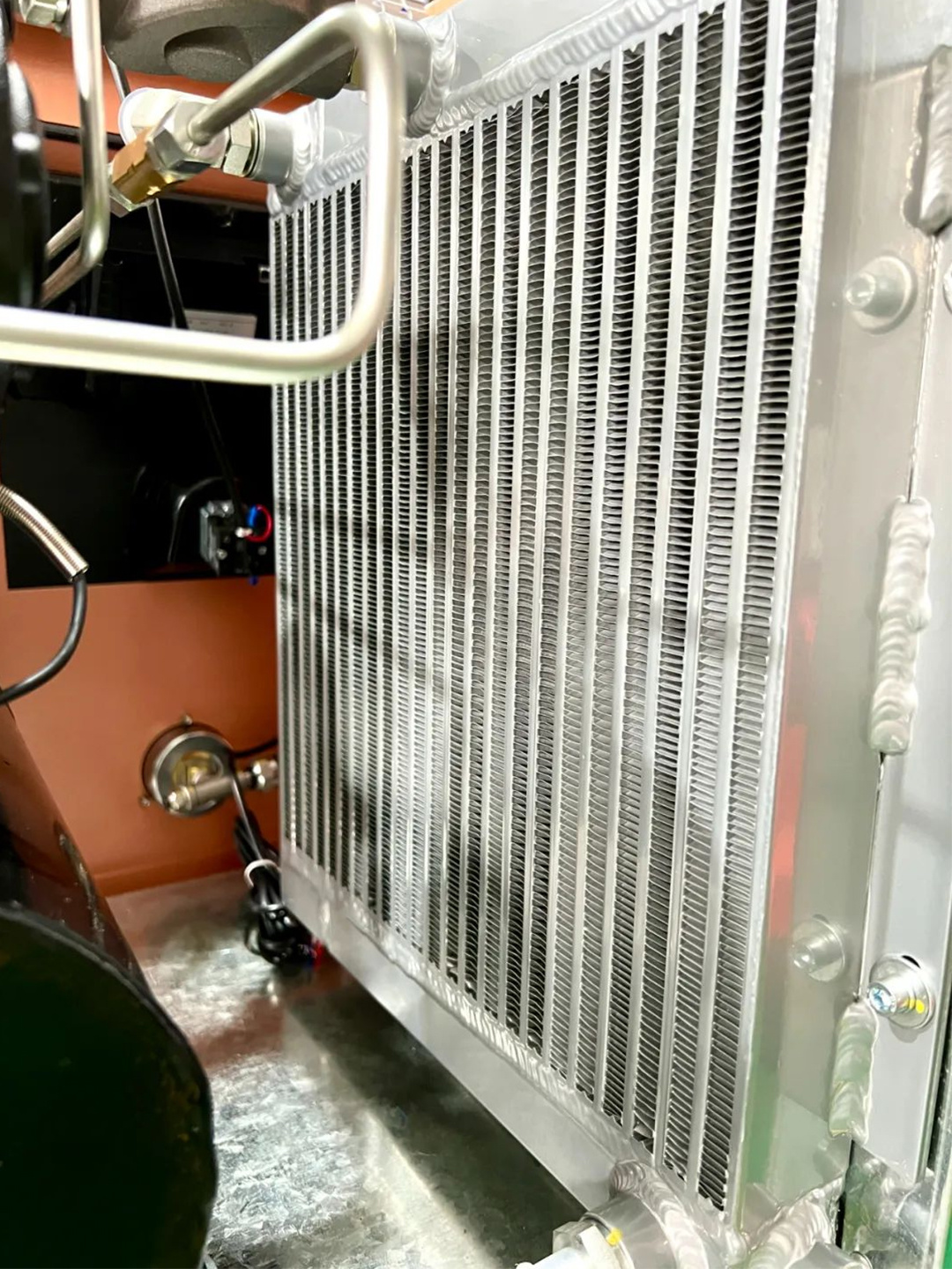

Cooling system inspection

Water-cooled models: Make sure that the cooling water inlet pressure is normal, usually around 0.2-0.4 kg. Check the temperature difference between the inlet and outlet pipes, and also adjust the temperature when entering the water to compensate for the rise in ambient temperature to ensure it is suitable for summer conditions.

Air-cooled models: regularly check whether there are dust and foreign objects blocking the fins of the radiator that need to be cleaned, and check whether the fins are corroded, and if so, they need to be replaced in a timely manner.

05

Original consumables maintenance

According to the product manual on time to use the original consumables for maintenance, quality parts can ensure the quality of compressed air in addition to effectively reduce the probability of machine failure in high temperature environment.

One of the most important consumables is the oil. Poor quality air compressor oil is easy to coke and has poor thermal stability, which makes it difficult to effectively take away the heat generated by the head operation.

Related news